TICKERS: AMY; AMYZ; 2AM

The Reser Report: Wanted—Domestic Electrolytic Manganese Metal

Source: Ken Reser, special to The Critical Metals Report††(7/26/11)

"The global shift to green energy has put pressure on metallurgical scientists to advance new applications. The days of infinite deposits and low base metals prices are over—forever."

"The global shift to green energy has put pressure on metallurgical scientists to advance new applications. The days of infinite deposits and low base metals prices are over—forever."

Historically, Electrolytic Manganese Metal (EMM) held a few basic critical and strategic uses, primarily in the alloying of steel, stainless steel and aluminum. Back in 1987, the U.S. government classified manganese as a strategic metal. This was not a new classification. It had been put in that category by the Dept. of Defense as far back as 1918. This high regard is not difficult to understand. No substitute metal exists for many steel applications. In fact, EMM has become a substitute for other, more expensive metals in certain alloys, including in stainless steel, thanks to innovative metallurgical discoveries.

Vast U.S. government strategic reserve stockpiles of manganese no longer exist. They are gone, sold off. Today, no domestic EMM suppliers operate in North America. China controls 97% of the world EMM trade. Manganese is the fourth-largest traded metal worldwide and you can't make steel without 10Ė20 pounds (lb.) of manganese per ton of steel, depending on the grade and type of steel.

Various refined forms of manganese, such as EMD (Electrolytic Manganese Dioxide), can be made from the same circuits and process as Electrolytic Manganese Metal. The United States is the largest consumer of EMD worldwide. Currently, battery consumption of EMD is predicted to be the fastest growing segment of manganese production worldwide. Chairman William Clay Ford Jr., of Ford Motor Company, predicts 25% of all Ford's future auto production will be electric vehicles by 2020. That would require a lot more batteries and a lot more manganese.

Changes are coming fast and furious in the broad spectrum of new applications for this strategic metal. The global shift to Green Energy has put pressure on metallurgical scientists to advance new applications of EMM to achieve weight, conductivity and durability requirements.

One of the first new widespread uses for EMM is in the cathodes of lithium-ion batteries for electric vehicles (EV). EMD is used in the anodes. This technology is already in use by GM's Chevy Volt, the Nissan Leaf and is in development by other automotive manufacturers. The Argonne National Laboratory in conjunction with Envia Systems has developed a high capacity manganese rich cathode battery said to hold twice the charge of other lithium-ion type batteries currently in use, can be recharged in a few minutes and is approximately half the weight of other EV storage batteries as well as having a lower production cost than other comparable lithium-ion type batteries currently under development.

The somewhat unspoken aspect of this new battery technology is the fact that every appliance, tool and EV using stored electricity will be revolutionized by this new discovery. Possible uses include marine and military vehicles, unmanned drones, forklifts, buses, even golf carts. Lithiated Manganese Dioxide (LMD) batteries are already being used by Milwaukee Tools in electric battery tools.

In addition to possessing a high power output and lower production costs, LMD batteries also exhibit high thermal stability and enhanced safety when compared to other lithium-ion batteries. The University of Illinois recently created an advanced prototype battery using lithiated manganese that can be recharged in as little as two minutes.

With an estimated 30M EVs sold worldwide in 2011 and an estimated 50M expected in sales by 2021, including larger vehicles coming to market using this technological innovation, the future for the EMM market looks bright, indeed.

On another innovative front, researchers at the College of Science and Engineering at the University of Minnesota developed an early-stage multi-ferroic alloy that converts heat directly into electricity. This consists of a combination of nickel, cobalt, manganese and tin. Professor and Research Team Leader Richard James said, "This research is very promising because it represents a new method for energy conversion that has never been done before." The team also states in their report that even though this technology is in the early stages of development, it could potentially be used to capture waste heat from vehicle exhaust that would produce electricity for charging car batteries. Another possibility includes rejected heat from industrial and power generation plants. This is just one more of the many emerging new scientific discoveries being made based on EMM.

Another example of constant change and innovation in the manganese sector is wind and solar farms grid electrical storage recently announced by researchers at the DOE Pacific Northwest National Laboratory and China's Wuhan University. Scientists developed a large-scale sodium, ion, manganese oxide battery that is more energy efficient and lower cost than lithium. This research is still early stage and ongoing.

The Days of Infinite Mineral Deposits and Low Base Metals Prices Are Over—Forever

History will show the transition that began as we entered the 21st century. China is showing us that transition by buying up strategic metals deposits and energy reserves around the world. Other nations will follow suit as time goes on. It is time for North America to wake up to this stark reality. Its name is "Protectionism."

While the U.S. is still imposing a 14% import tax on EMM and China is levying a 20% export tax, South Korea is now dropping its import tariffs on manganese. North America has no strategic reserve or domestic EMM mines, leaving China to control 98% of the global market. In 2010, world production of manganese ore stood at 47M tons. It seems that the time is ripe for a new player in the North American domestic EMM production field. We must achieve domestic production in order to remain globally competitive in the green energy, steel and other evolving sectors. The U.S. was the leader in world production for over 100 years. China's dominance of the EMM market truly represents a very serious supply threat to the rest of the world. We need a long-term EMM domestic supply chain—a supply chain that is not at the mercy of a competitor nor a potential adversary. One U.S.-based and very large advanced-stage EMM mine project in Arizona could potentially fill that critical need.

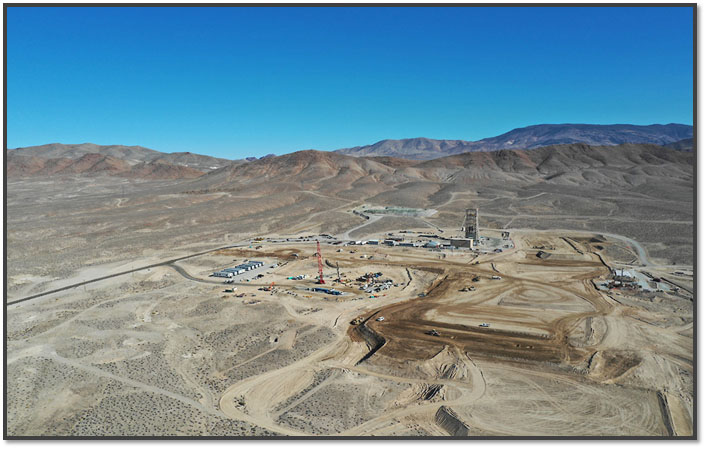

Due to the extensive and advanced-stage work currently being accomplished by American Manganese Inc. (TSX.V:AMY; OTCPK:AMYZF) at their Artillery Peak Arizona manganese deposit (current NI 43-101 resource, indicated 6.76 Blb. and inferred 8.8 Blb.), the USGS and Arizona Geological Survey (AZGS) are now showing substantial renewed interest in the area and project. The AZGS is now undertaking the remapping and defining of the manganese and other minerals in the Artillery area. The USGS has termed the Artillery Peak deposit as the largest low-grade manganese deposit in the U.S. since the 1940s.

American Manganese, subsequent to previous work by the U.S. Bureau of Mines commissioned by the U.S. government in World War II, is now leading the way in becoming the next and only EMM producer in the U.S. This prior research led to the creation of an operating plant at Three Kids, Nevada. Concurrent with this, the Bureau of Mines created a process for producing EMM. This process for EMM manufacture is used today in China and South Africa. A variation of this electrolytic process has now been updated and revamped through new technology and design for American Manganese Inc. by Kemetco Research Inc., and has already been placed under U.S. Patent application.

With extremely high electrical costs in China and South Africa as well as depleting domestic supplies of manganese in China, both countries are producing EMM at or about $1.30/lb. The EMM price in June was $1.54 FOB Rotterdam, $1.80 FOB U.S. East Coast (including the 14% import duty). The Preliminary Economic Assessment (PEA) 2009 study completed for American Manganese has a NI 43-101 estimated cost per pound of production at $0.44.

With this updated, robust and energy-efficient process developed by Kemetco and American Manganese, mining EMM is now entering the realm of green mining technology with greater than 90% extraction rates through low electrical and minimal water usage. The mining process also ends up with benign toxicity in tailings, which can be replaced immediately into reclamation areas. A continuous bench scale test pilot facility is currently being built for further testing of up to 20 tons of Artillery Peak manganese oxide ore to further prove this patent-pending process, which is expected to be completed in August 2011. Wardrop (a Tetra Tech Co.) is currently engaged in preparing the Artillery project pre-feasibility study.

It would appear that the U.S. is on the threshold of having a potential world-class, domestic EMM supply with a low cost and minimal impact some time in 2014. This at a time in history when EMM finds new, large-scale demands in green energy, electronics, specialty steels and aluminum alloys, and a world ever-growing and expanding, not to mention one with much neglected old and out-dated infrastructure needing replacement and upgrading.

The world's need for critical metals is infinite, but the resources are not.

Ken Reser, an independent mining consultant, has over 20 years of direct involvement in the gold mining market industry, as well as having been a placer gold miner for a number of years in Yukon and British Columbia. Since 1990, he has had significant investor and public relations experience with junior base metal miners, gold, diamond and oil explorationists. Ken has consulted on gold exploration and prospecting projects in Ghana and Bolivia, as well as having staked his own extensive mineral claims in Lac De Gras, NWT, British Columbia and Yukon. He is a founding member of the Gold Anti-Trust Action Committee (GATA) and he is presently involved in an R&D consulting capacity for various Canadian junior mining companies. Since 2005, he has been actively writing mining editorials on various topics, including molybdenum, manganese, magnesium and gold. He can be reached at (403) 844-2914.

Disclaimer:

The author is not an investment advisor and as such this report is not to be construed as a recommendation to buy or own shares in any aforementioned companies. The author may own shares in said companies and is currently a paid consultant to American Manganese Inc.

Vast U.S. government strategic reserve stockpiles of manganese no longer exist. They are gone, sold off. Today, no domestic EMM suppliers operate in North America. China controls 97% of the world EMM trade. Manganese is the fourth-largest traded metal worldwide and you can't make steel without 10Ė20 pounds (lb.) of manganese per ton of steel, depending on the grade and type of steel.

Various refined forms of manganese, such as EMD (Electrolytic Manganese Dioxide), can be made from the same circuits and process as Electrolytic Manganese Metal. The United States is the largest consumer of EMD worldwide. Currently, battery consumption of EMD is predicted to be the fastest growing segment of manganese production worldwide. Chairman William Clay Ford Jr., of Ford Motor Company, predicts 25% of all Ford's future auto production will be electric vehicles by 2020. That would require a lot more batteries and a lot more manganese.

Changes are coming fast and furious in the broad spectrum of new applications for this strategic metal. The global shift to Green Energy has put pressure on metallurgical scientists to advance new applications of EMM to achieve weight, conductivity and durability requirements.

One of the first new widespread uses for EMM is in the cathodes of lithium-ion batteries for electric vehicles (EV). EMD is used in the anodes. This technology is already in use by GM's Chevy Volt, the Nissan Leaf and is in development by other automotive manufacturers. The Argonne National Laboratory in conjunction with Envia Systems has developed a high capacity manganese rich cathode battery said to hold twice the charge of other lithium-ion type batteries currently in use, can be recharged in a few minutes and is approximately half the weight of other EV storage batteries as well as having a lower production cost than other comparable lithium-ion type batteries currently under development.

The somewhat unspoken aspect of this new battery technology is the fact that every appliance, tool and EV using stored electricity will be revolutionized by this new discovery. Possible uses include marine and military vehicles, unmanned drones, forklifts, buses, even golf carts. Lithiated Manganese Dioxide (LMD) batteries are already being used by Milwaukee Tools in electric battery tools.

In addition to possessing a high power output and lower production costs, LMD batteries also exhibit high thermal stability and enhanced safety when compared to other lithium-ion batteries. The University of Illinois recently created an advanced prototype battery using lithiated manganese that can be recharged in as little as two minutes.

With an estimated 30M EVs sold worldwide in 2011 and an estimated 50M expected in sales by 2021, including larger vehicles coming to market using this technological innovation, the future for the EMM market looks bright, indeed.

On another innovative front, researchers at the College of Science and Engineering at the University of Minnesota developed an early-stage multi-ferroic alloy that converts heat directly into electricity. This consists of a combination of nickel, cobalt, manganese and tin. Professor and Research Team Leader Richard James said, "This research is very promising because it represents a new method for energy conversion that has never been done before." The team also states in their report that even though this technology is in the early stages of development, it could potentially be used to capture waste heat from vehicle exhaust that would produce electricity for charging car batteries. Another possibility includes rejected heat from industrial and power generation plants. This is just one more of the many emerging new scientific discoveries being made based on EMM.

Another example of constant change and innovation in the manganese sector is wind and solar farms grid electrical storage recently announced by researchers at the DOE Pacific Northwest National Laboratory and China's Wuhan University. Scientists developed a large-scale sodium, ion, manganese oxide battery that is more energy efficient and lower cost than lithium. This research is still early stage and ongoing.

The Days of Infinite Mineral Deposits and Low Base Metals Prices Are Over—Forever

History will show the transition that began as we entered the 21st century. China is showing us that transition by buying up strategic metals deposits and energy reserves around the world. Other nations will follow suit as time goes on. It is time for North America to wake up to this stark reality. Its name is "Protectionism."

While the U.S. is still imposing a 14% import tax on EMM and China is levying a 20% export tax, South Korea is now dropping its import tariffs on manganese. North America has no strategic reserve or domestic EMM mines, leaving China to control 98% of the global market. In 2010, world production of manganese ore stood at 47M tons. It seems that the time is ripe for a new player in the North American domestic EMM production field. We must achieve domestic production in order to remain globally competitive in the green energy, steel and other evolving sectors. The U.S. was the leader in world production for over 100 years. China's dominance of the EMM market truly represents a very serious supply threat to the rest of the world. We need a long-term EMM domestic supply chain—a supply chain that is not at the mercy of a competitor nor a potential adversary. One U.S.-based and very large advanced-stage EMM mine project in Arizona could potentially fill that critical need.

Due to the extensive and advanced-stage work currently being accomplished by American Manganese Inc. (TSX.V:AMY; OTCPK:AMYZF) at their Artillery Peak Arizona manganese deposit (current NI 43-101 resource, indicated 6.76 Blb. and inferred 8.8 Blb.), the USGS and Arizona Geological Survey (AZGS) are now showing substantial renewed interest in the area and project. The AZGS is now undertaking the remapping and defining of the manganese and other minerals in the Artillery area. The USGS has termed the Artillery Peak deposit as the largest low-grade manganese deposit in the U.S. since the 1940s.

American Manganese, subsequent to previous work by the U.S. Bureau of Mines commissioned by the U.S. government in World War II, is now leading the way in becoming the next and only EMM producer in the U.S. This prior research led to the creation of an operating plant at Three Kids, Nevada. Concurrent with this, the Bureau of Mines created a process for producing EMM. This process for EMM manufacture is used today in China and South Africa. A variation of this electrolytic process has now been updated and revamped through new technology and design for American Manganese Inc. by Kemetco Research Inc., and has already been placed under U.S. Patent application.

With extremely high electrical costs in China and South Africa as well as depleting domestic supplies of manganese in China, both countries are producing EMM at or about $1.30/lb. The EMM price in June was $1.54 FOB Rotterdam, $1.80 FOB U.S. East Coast (including the 14% import duty). The Preliminary Economic Assessment (PEA) 2009 study completed for American Manganese has a NI 43-101 estimated cost per pound of production at $0.44.

With this updated, robust and energy-efficient process developed by Kemetco and American Manganese, mining EMM is now entering the realm of green mining technology with greater than 90% extraction rates through low electrical and minimal water usage. The mining process also ends up with benign toxicity in tailings, which can be replaced immediately into reclamation areas. A continuous bench scale test pilot facility is currently being built for further testing of up to 20 tons of Artillery Peak manganese oxide ore to further prove this patent-pending process, which is expected to be completed in August 2011. Wardrop (a Tetra Tech Co.) is currently engaged in preparing the Artillery project pre-feasibility study.

It would appear that the U.S. is on the threshold of having a potential world-class, domestic EMM supply with a low cost and minimal impact some time in 2014. This at a time in history when EMM finds new, large-scale demands in green energy, electronics, specialty steels and aluminum alloys, and a world ever-growing and expanding, not to mention one with much neglected old and out-dated infrastructure needing replacement and upgrading.

The world's need for critical metals is infinite, but the resources are not.

Ken Reser, an independent mining consultant, has over 20 years of direct involvement in the gold mining market industry, as well as having been a placer gold miner for a number of years in Yukon and British Columbia. Since 1990, he has had significant investor and public relations experience with junior base metal miners, gold, diamond and oil explorationists. Ken has consulted on gold exploration and prospecting projects in Ghana and Bolivia, as well as having staked his own extensive mineral claims in Lac De Gras, NWT, British Columbia and Yukon. He is a founding member of the Gold Anti-Trust Action Committee (GATA) and he is presently involved in an R&D consulting capacity for various Canadian junior mining companies. Since 2005, he has been actively writing mining editorials on various topics, including molybdenum, manganese, magnesium and gold. He can be reached at (403) 844-2914.

Disclaimer:

The author is not an investment advisor and as such this report is not to be construed as a recommendation to buy or own shares in any aforementioned companies. The author may own shares in said companies and is currently a paid consultant to American Manganese Inc.